In today's era of manual creativity and individual expression, a high-quality and professional design component can often become an important factor in determining the success or failure of a work. T302.5A fine toy wheel is such a high-quality plastic wheel product that integrates precision manufacturing, versatility and practicality. It is specially designed for model makers who pursue the ultimate details.

the choice of ingenuity | T302.5A fine toy wheel to create the beauty of model details

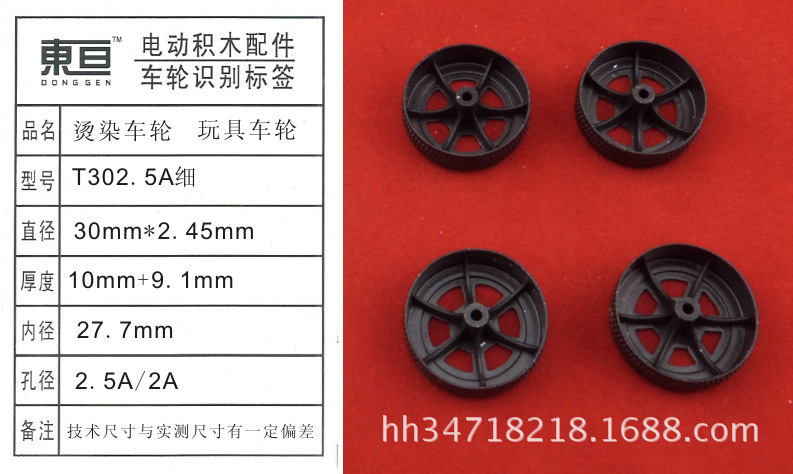

This is a toy wheel model called "the ideal accessory" by countless hand lovers. It is produced by advanced CNC die-casting process, and the size error of each product is controlled within a very small range, ensuring a highly consistent assembly performance. Whether it is used to assemble static furnishings or dynamic running devices, it can show a satisfactory balance of beauty.

In addition to the precise geometric shape, its edges have been carefully polished by hand, and it feels round and tingling. It is particularly intimate in the operating environment of frequent contact. The material itself has good heat resistance properties, can maintain structural integrity under different temperature conditions, and is not easy to age and deform. It is one of the preferred materials for long-term use.

Application Scenario Exploration | All-round Partner from Children's Educational Assembly to High-end Customized Model

Although it is named "toy wheel", its use is far more than simple children's game props. In fact, due to the standardized interface design, the 2.5 plastic wheel with a diameter of 30mm can be easily embedded in various types of mechanical components.

whether it is a small cart kit for home entertainment, a power transmission module for collectible remote control vehicles, or even a core component of some engineering teaching experimental teaching aids, this wheel can be competent. Not only that, it has good adsorption of dye, which is convenient for users to spray paint and beautify according to the theme style, and further release personalized imagination space.

Interpretation of process highlights | Advanced ironing technology achieves perfect contour consistency

In order to break through the problem of flash defects that are easy to produce in traditional plastic products, the manufacturer has introduced a fully automatic ultrasonic trimming system to participate in the final finishing process. The application of this technology allows each factory unit to have a cutting line that is as sharp and neat as a metal part.

combined with strict molecular arrangement control means and scientific cooling and shaping process, these plastic wheels can not only maintain their original shape in low temperature and humid environment, but also quickly restore their original shape after being subjected to slight bending pressure, thus greatly improving the overall anti fatigue strength and reuse value.

Shopping Worry-Free Commitment | Source Platform Support One-Stop Procurement Service System Upgrade

Relying on the research and development background of the deep-cultivated industry for many years and the strong production capacity of more than 1 billion pieces per year, the supplier has established a perfect service system to respond to the diversified needs of customers from all over the world. Whether it's individual replacement of sporadic damaged parts or mass customization of large orders by enterprises, we always insist on responding with the highest efficiency.

the entire transaction process is transparent and controllable, and buyers can check the location information of the package at any time through the background until the receipt is confirmed. More importantly, all valid purchases made on this platform will enjoy the bonus of free shipping policy by default, which truly realizes the double favorable situation of convenience value-added and cost reduction.